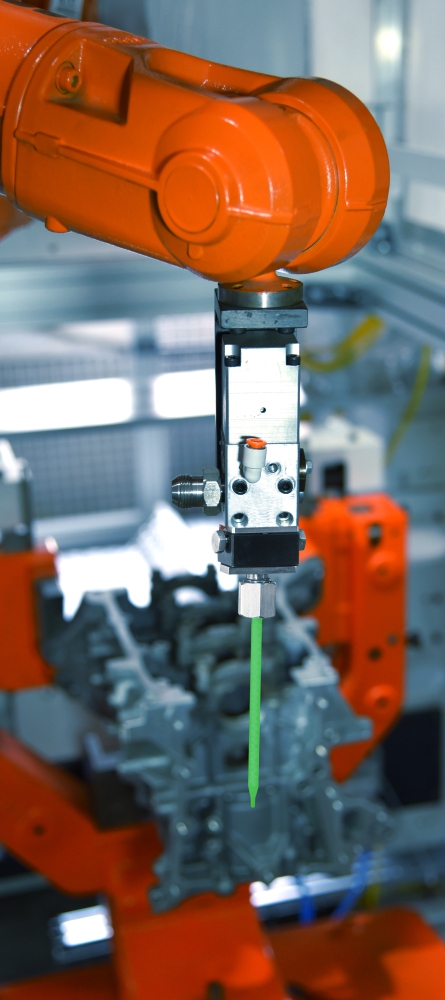

Elastomer Cast Polyurethane Machines

Cast Elastomer Polyurethane Machines for MDI, TDI and NDI Processes. India’s highest-selling. Exports to Thailand, Dubai and Australia.

Applications: PU Bushings l PU Rollers l PU Mats l Caster Wheels | PU Disks

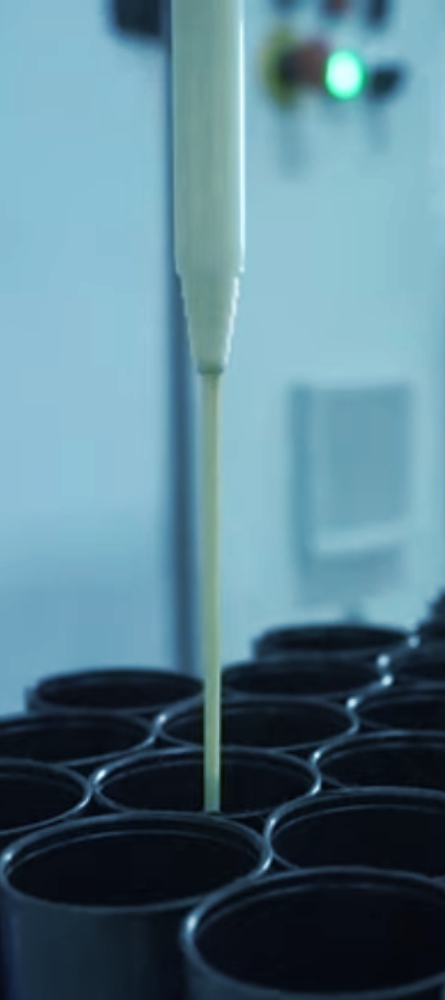

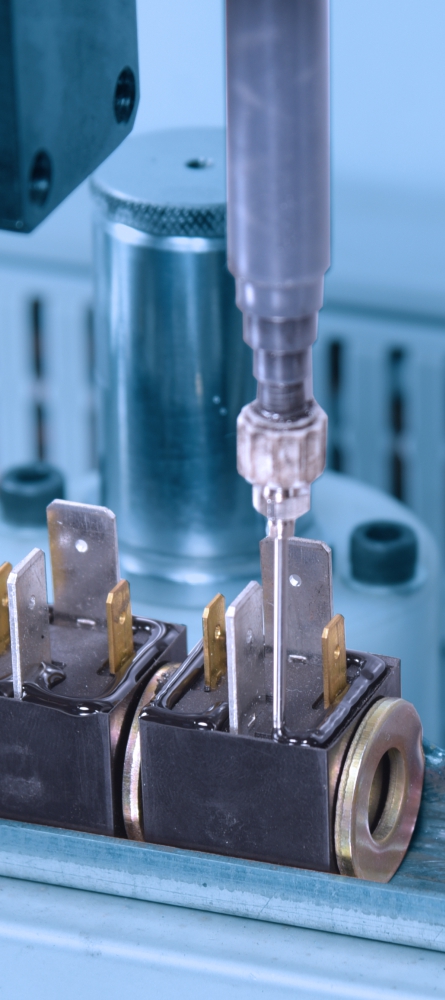

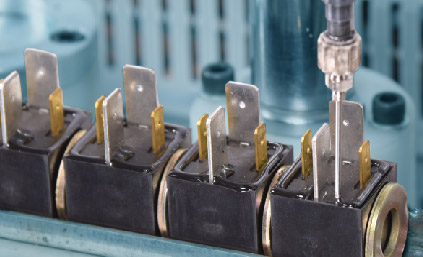

Electronic Potting: Auto-Electronics l Capacitors | LED Drivers and SPDs | Electric Vehicles | Motors

Process: Atmospheric and Vacuum Potting

Products: Tabletop Dispensers, Standard Meter Mix Machines, Fully Automated production lines for dispensing PU and/or Epoxy.

Epoxy Casting Plants for Electrical Transformers and Bushings

Twin Engineers offers machines for Atmospheric Casting and semi or fully automated Epoxy Casting Plants, including silica filling, with options of integration with vacuum chamber or multiple APG Stations.

Applications: Low Voltage CT/PTs l Bushings and Insulators l Dry Type Transformers

Epoxy Resin Dispensing for Composites

Twin’s Machines serve all the key application methods in composite production including Epoxy Baths in filament winding, Pultrusion, Resin Infusion, Gel Coating along with Bonding and Sealing of composite parts. Twin’s Machines are well proven for reliability even under extreme conditions and very high production volumes.

Applications: Wind Rotor Blades l Sports & leisure l Electrical and Electronics l Tanks & Pipes

Why choose Twin

Why choose Twin

Industry 4.0 Machines

NextGen Packaging New

Twin’s Adhesive Dispensing Pumps help India’s Laminator Manufacturers win in global markets

Wifi and Mobile enabled Pack Pumps with advanced controls, near-zero maintenance and years of uninterrupted production.