Precise and consistent mixing and application of epoxy resin for producing high-quality composite parts.

for Composite Parts in Aerospace, Automotive, Marine, Wind Rotor Blades, Sports Goods and Construction

Modal Box Title

Modal Box Content

Trickle Varnish Impregnation Plants

for Hub Motor, BSG, IPM BLDC, Synchronous Motor

Seamless at every scale.

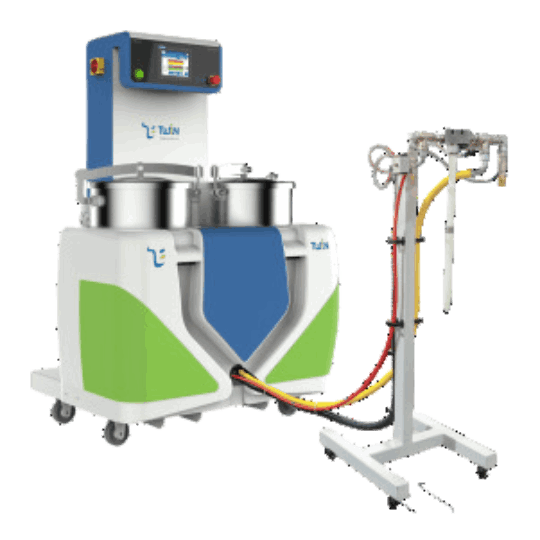

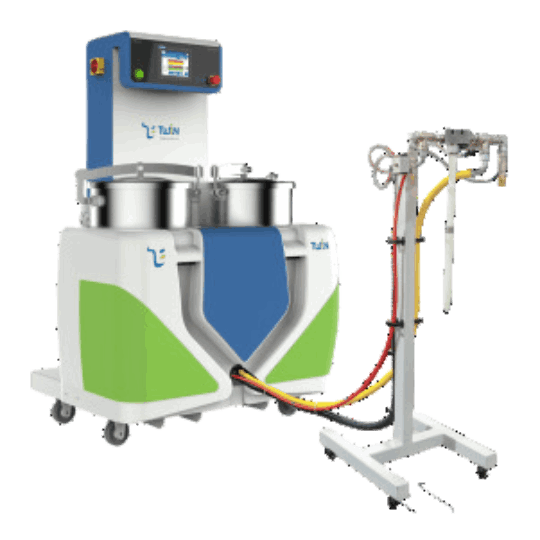

Complete solution for Hand Layup with innovative attachments

Achieve accurate ratio. Defect-free parts. Cost-effective process

Twin’s machines for Hand Layup ensure the epoxy resin and hardener are mixed in the correct ratios, to achieve critical mechanical properties and durability of the composite part. Fully automated mixing and dispensing minimize resin waste compared to manual mixing, making the process more cost-effective. Automation speeds up the process, allowing for higher production rates and better utilization of labor.

Consistent application of the mixed epoxy improves the uniformity and quality of the composite parts, reducing the likelihood of defects.

The Machines help reduce the exposure of workers to harmful chemicals, enhancing workplace safety.

Benefit from Twin's advanced mixing and dispensing technology

100% Accurate Mixing Ratio

Variable Ratio Systems

Processing materials with wide range of viscosities

IoT for data management and preventive maintenance

Clean, contamination-free process

Operator friendly, and programmable process recipes

Easy cleaning and maintenance

24 X 7 Service Support

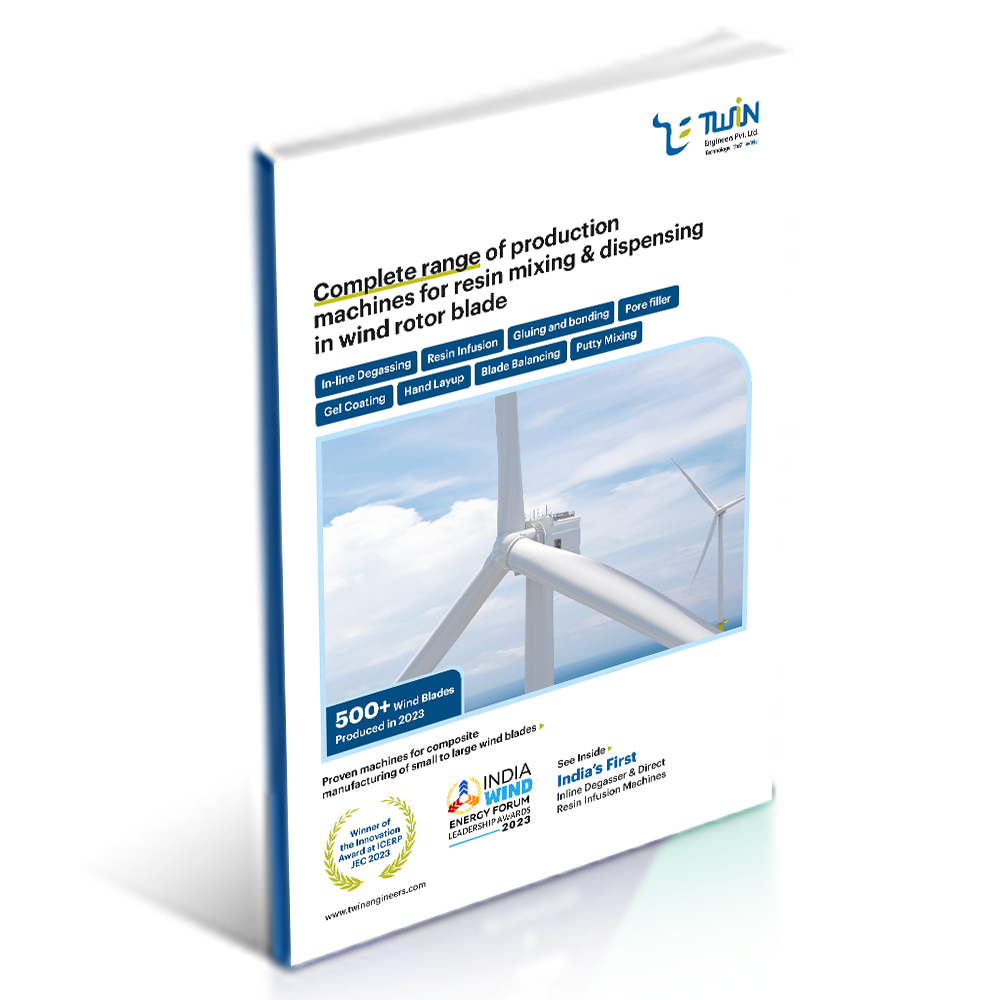

Download Catalog 2024

Want to browse the entire range of our products at your leisure?

Get your FREE copy of the latest Product Catalog.

Complete range, customised to your needs

Meet the Award Winner! Online Direct Infusion Machine

•

April 26, 2024

Twin Engineers proudly announces its

Tackling the 5 Challenges in Resin Infusion in Wind Rotor Blades

•

April 19, 2024

Wind blade manufacturers face significant

Choose your machine with our Expert

Sanchita Bhalwankar

Expert in Composite Processes

- +91 99755 49703

- mktg@twinengineers.com