5 Smart ways to achieve Zero Air Bubble in On Board Chargers Potting.

This German OBC manufacturer needed precise, bubble-free potting with full flexibility for future models. Specially get a go ahead from their customer by showcasing NO air bubbles. And it had to be done in less than 16 weeks.

For the manufacturing plant in Vietnam Perfect Potting isn’t just a requirement-it’s the foundation of their reputation. As a world-class manufacturer, they supply high-quality on board chargers globally.

But with every new variety, the game changed.

Circuit designs kept evolving. Potting quantities varied. Component geometries changed. And customer rejected a job with slightest bubbles.

For their latest project, they faced a critical challenge:

A tricky PU formulation which is extremely moisture sensitive requiring a precise 100:8 mixing ratio

A 400gm to 1kg is the Potting quantity variation, demanding extreme accuracy

100% bubble free is the target to win the customer’s heart for chargers potting.

The Reality: All variants gave bubbles after potting!

The company explored multiple options, but every solution came with serious drawbacks:

Lack of flexibility – Conventional machines weren’t adaptable.

High investment, high risk – Importing a system cost 3-4x more, came with 6-8 month delivery times, and still lacked flexibility.

Lack of Process knowledge with vendors they chose – Bubble formation and mixing inconsistencies risked the production output. And no one knew the right process.

They needed a total solution.- one that would guarantee 100% bubble-free potting, maintain Potting compound weight, and adapt effortlessly to future design changes.

Partnered with Twin, not just for a machine – but for a complete, future-proof potting process with one goal to achieve 100% Bubble free Potting and win the customer’s heart.

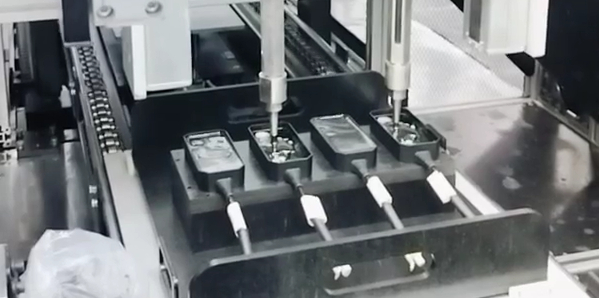

Fully Integrated Automation – A complete system with double head with independent axes, vacuum chamber for degassing ensuring perfect repeatability and no operator dependency.

100% Flexibility – Designed to reconfigure easily for different sizes of the jobs, shot sizes, and component geometries-future-proofing investment.

Delivered in Just 12 Weeks – A fraction of the time compared to imported solutions, with zero risk in implementation.

The Result: Zero air bubbles and a happy end customer!

Such smallest air bubble was rejected by the end customer.

100% data maintained for every OBC – Twin’s precision control eliminated bubble formation and mix ratio inconsistencies and gathered data for customer audit for each job with Potting quantities dispensed

Key Takeaway: A partner who knows the Process can give you the results that you want!

Most potting machines force manufacturers to adjust their process to fit the machine. But with Twin’s expertise, I got a solution designed around their needs-one that works today and adapts effortlessly for tomorrow.

This company made the right call. Ready to make yours?

The Challenge: Potting That Keeps Up With Change

- Constant changes in OBC designs, shot sizes from 0.4kg to 1kg

- Constant rejection from their customers for the smallest air bubble

- Tricky 100:8 PU mix

- 100% bubble-free requirement

- Existing machines lacked flexibility, imported ones too rigid to make the change

Twin’s Solution: Flexible, result orientated to solve your problem!

- Double-head, independently controlled dispensing with post-dispensing vacuum

- Configurable for varying shot sizes, job sizes, and geometries

- Delivered in just 12 weeks, ready for future model changes

The Outcome: Zero Bubbles, Full Control

- Zero rejection- The end customer accepted the jobs happily!

- 100% traceable potting data for every OBC

- Seamless shift to new models without new machines or rework