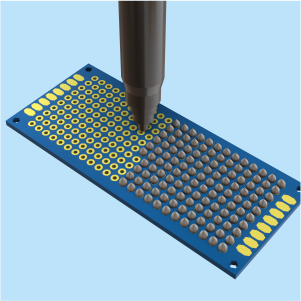

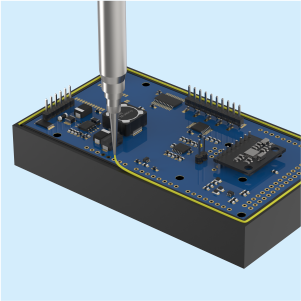

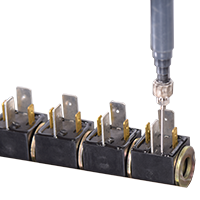

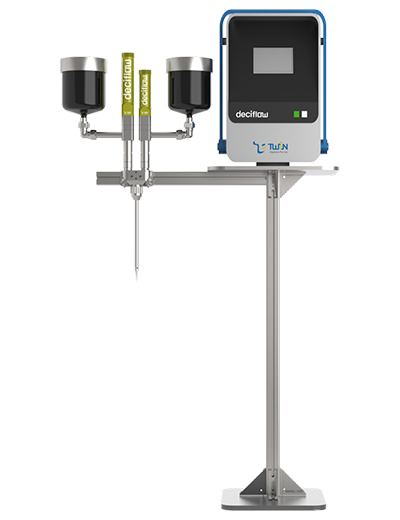

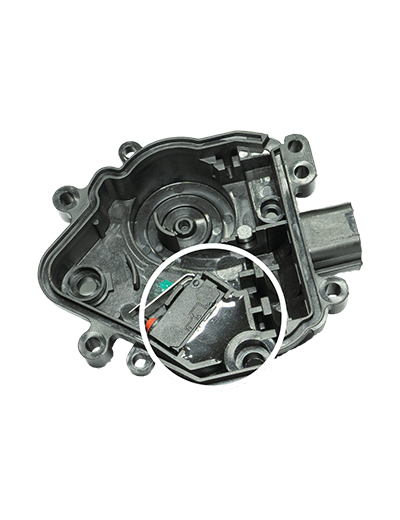

Meter Mix Dispensing Machines for Atmospheric Potting

for Sensors, ECUs, PCBs, LEDs, and many more..

Modal Box Title

Modal Box Content

Trickle Varnish Impregnation Plants

for Hub Motor, BSG, IPM BLDC, Synchronous Motor

Seamless at every scale.

Complete range of Machines for Wind-Blade Manufacturing

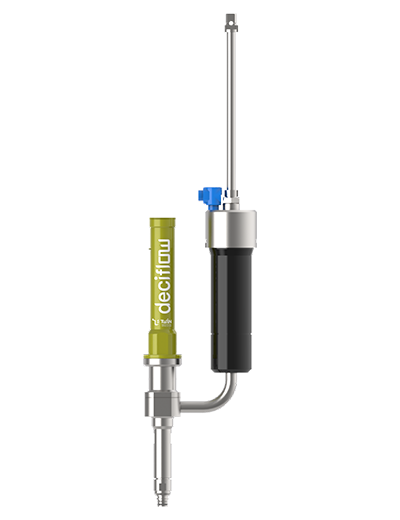

Single Component

Suitable material package

Cartridge or Tanks

Viscosity

Thixotropic to watery thin liquid

Flow Rate

0.2 gm/seconds

Pump with Controller

Suitable material package Suitalbe

Cartridge or Tanks

Flow Rate

0.2 gm/second

Mixing Ratio

100:5 to 100:100

Table Top Dispenser

Suitable material package

Tanks (0.5 L to 5 L)

Flow Rate

0.2 gm/second

Mixing Ratio

100:5 to 100:100

Automation Options

High-speed. Continuous Potting. 100% Accurate. For dispensing volume as low as 0.01 gms.

Whether it is about dispensing liquids or thick pastes, mixing materials with diverse viscosities, or ensuring high-precision, accurate, and repeatable dispensing, at high-speed, we have the solution that fits your goals and budgets.

Benefit from Twin's advanced mixing and dispensing technology

Minimise

High Quality

Reliable

Optimise time and manpower

Monitor productivity

Single point solution

Complete range, customised to your needs

- 100% Bubble free potting

- Save costs with over 80% reduction in rejections70%

- Time savings on product trials

- Eliminate 100% manual errors in dispensing

- Processing of media with wide range of viscosity

- Dispensing accuracy of ± 1%

- Repeatability of ± 99%

- PLC based controller

- Precision pumps for metering

- Suck-back gun

- Easy dispensing integration for handheld and automation options

Complete range, customised to your needs

Speed vs Quality Trade Off, No More!

•

November 29, 2025

Case Study How one automated

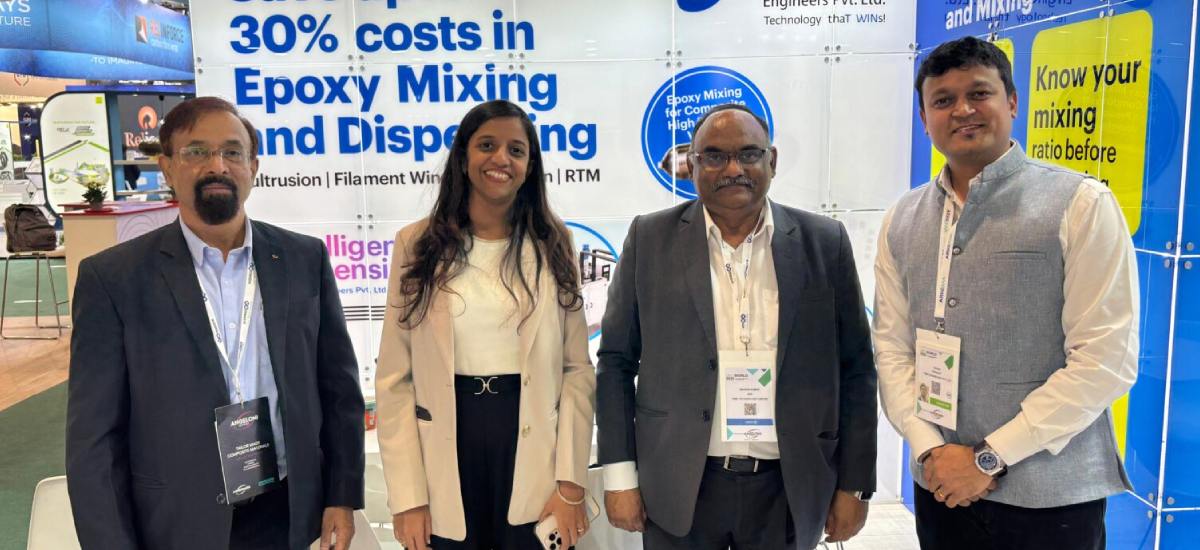

Woman in Composites – Journey of Sanchita Bhalwankar, Director Twin Engineers Featured in JEC World

•

May 19, 2025

“My journey is not just

5 mistakes to Avoid in Vacuum Potting

•

August 1, 2024

In view of expanding to

Choose your machine with our Expert

Sanchita Bhalwankar

Expert in potting prcoesses

- +91 9804169804

- mktg@twinengineers.com