Adhesive Dispensing and Fluid Filling in Electric Vehicles

Full-range of Solutions for Electric Vehicles

The range of electronic controls in an automotive is increasing rapidly. With the Electric Vehicles the scope only expands further. Twin Engineers is a technology partner to several of the world’s leading automotive manufacturers. As these companies begin their endeavour to switch to the Electric Vehicles. Twin Engineers continues to be valuable partner to enable this change.

Simultaneously, Twin Engineers is also engaged with several niche parts and vehicle manufacturers who are setting new waves in the fast evolving EV technology spectrum.

Our Advantages

Applications we serve

1. LED Lights

Production of LED lights for automotive requires fast yet easy automation. Twin’s technology for LEDs includes potting for LED Drivers, LED light strips of various sizes.

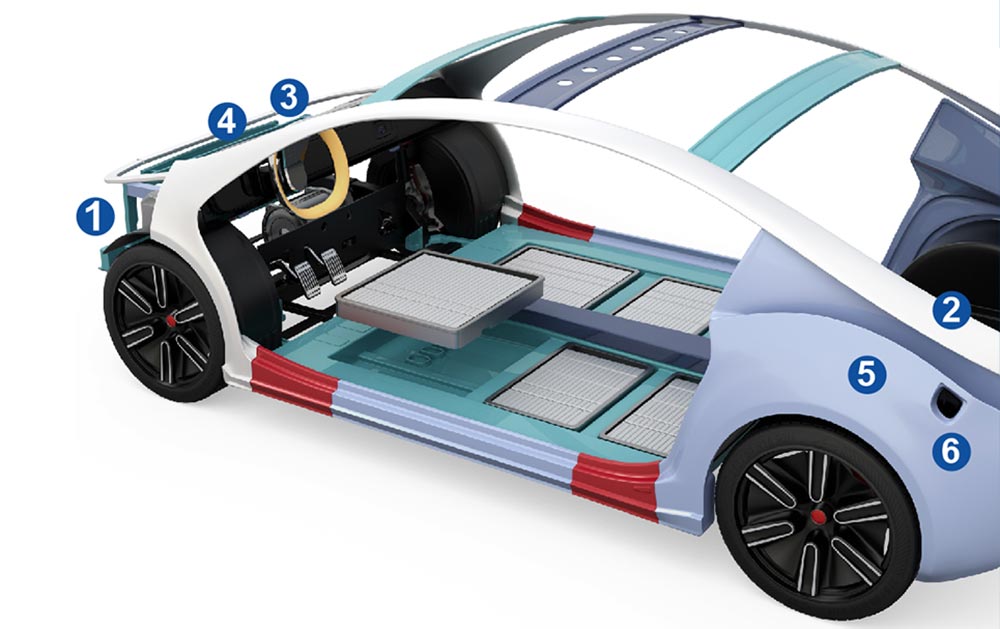

2. Battery Packs

EVs use high voltage battery units that need sealing and bonding at various stages. From pasting the battery packs to the EVs to applications of various pastes or circulation of fluids to ensure thermal management of these batteries.

3. Electric Motors

Dispensing of 2 Part Epoxy inside the cavity of the rotor holding the magnets is important to functioning of the motors such as Impregnated permanent magnet motors or Switch reluctance motors.

4. Power Electronics

Twin’s advanced vacuum potting technology ensures permanent protection long lasting, and reliable performance of a variety of power electronic components used in EVs. Starting from DC Converters to advanced Capacitors Twin Engineers has the solution with multiple automation options for your specific applications.

5. Sensors

The high-end EVs in the market could use anywhere between 100 to 250 sensors in it. Starting from the regular parking sensors to highly advanced sensors used in thermal management of batteries, Twin Engineers can provide solution for all kinds of sensor applications for the EVs.

6. Charging Stations

The outdoor charging station plugs are exposed to highly adverse environment. The charging facility has to function safely no matter the ambient temperature, moisture level or dust and other form of pollution. The potting of chargers is critical to ensuring a long life and seamless performance of these stations.

Machines we offer