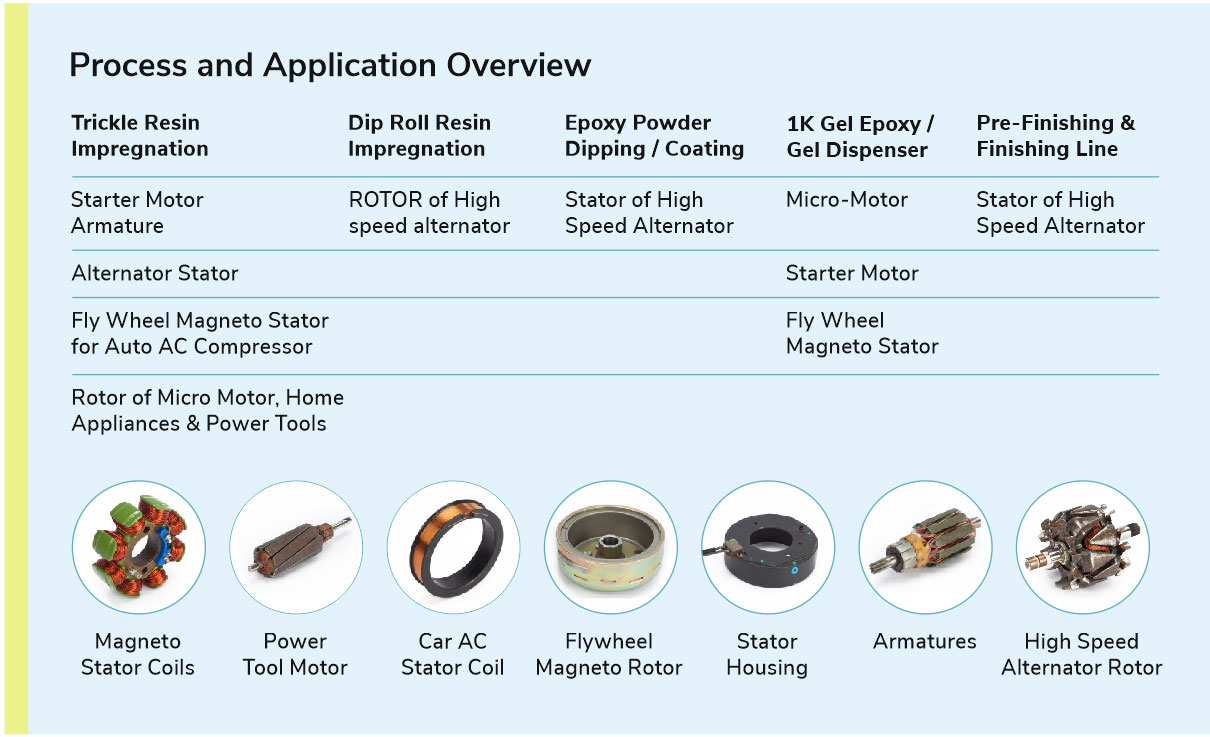

Automotive Electrical Components

Fully automated plants for Powder Coating, Impregnation and finishing lines of hybrid and electrical motors, electrical components and wound objects

Compact and Automated Production Lines

Varnishing of electrical winding is a key cost center for manufacturers of hybrid and electrical motors. With increasing volume, more compact motor designs and faster cycle times, conventional methods of electrical insulation are not economical. Twin offers a complete solution for automated impregnation of stators, field armatures or rotors including powder coating, heating and curing processes.

Proven Modules

Powder Impregnation

Fluidized bed powder coating system for improved resistance

Twin’s module applies the epoxy powder on the component through an electrostatic fluid bed process, and cured by means of an induction coil or resistance heating.

SPECIFICATION

- Depth of Powder Up to 250 mm, Fluidized Height : 250 +/- 5 mm

- Powder Coating quantity 8 gm +/- 1 gm

- Coating Height 6 mm

FEATURES

- Automated pick and place

- Rotation of the component

- Powder dispensing with servo controlled screw

- Laser and Infra Red Temperature Sensor

Trickle Varnish Impregnation and hot dip

For energy efficient impregnation with very short cycle time

Twin’s trickle impregnation plants are designed and configured for production rate, size and shape of the component, for a variety of trickle resin used in your process.

AUTOMATION OPTIONS

- Batch type, multi-spindle trickle impregnation mostly suitable for AC motors

- Rotary indexing type plant ideal for medium to small sized stators & rotors

- Conveyorised Trickle Impregnation Plant is suitable for high volume of production

Roll Dip Impregnation

For high quality impregnation in very short cycle time

The Roll Dip method, suitable for rotors and stators. Twin offers an integrated solution for different phases of the process including preheating, impregnation, gelation, curing and cooling. The control parameters such as rotations, speed and dipping level are configured to achieve optimum resin penetration inside the component slots.

FEATURES

- Quick mounting for accurate connections to resistance heating

- Precise temperature control of the winding

- Precision dispensing for resin quantity as per the component

- Modular design with Weighing arrangement pre and post varnishing

- Data Logging for component level traceability

Finishing Line Automation

For improved resistance to moisture, workplace contaminants and chemicals

The epoxy gel is dispensed and applied with a brush, automatically on the motor and designed specifically to suit the geometry of the component.