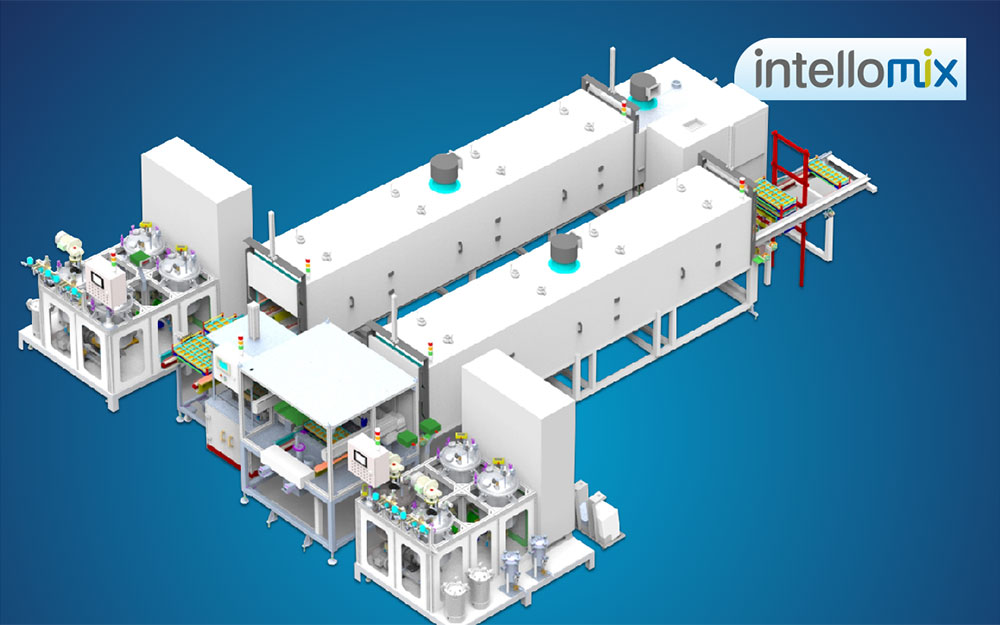

Intellomix- Fully Automatic Potting Line

Watch Video

Download BrochureEnd-to-End Solution Customized to Your Needs

Twin’s process automation for complete production line leverages it’s proven technology in atmospheric and vacuum potting to further integrate it with complementary systems that automate all other tasks in the process. From defining the process requirement right up to proving the line, Twin truly serves with an end-to-end support by integrating every aspect involved in automating your potting process.

Applications

Ignition Coils

CDI, Flashers, ECUs, Relays

Key Benefits

Technical Specifications

| Tank Capacity | 35 L | 60 L | 100 L |

| Material | PU, Epoxy |

| System | 2/3/4 tank system |

| Flow Rate | 0.5 g/sec to 1kg/min |

Standard Features

– Precision gear mixing

– Touch Screen HMI

– Vacuum degassing

– Electric Heating

– Motorised Stirrer

– Programmable recipes

– Static Mixer

– Stainless steel Tanks

– Pressure Transmitters

– Level Sensors

– Vacuum Chamber

– Conveyor based component feeding

– Vacuum Chamber

– X-Y Robotic Dispensing

Optional Features

– Multi-head dispensing

– Programable recipes for multi-stage potting

– Production monitoring on mobile

– Vacuum Chamber configuration as per process need