Potting for NextGen ECUs

Know more…

Client: Fast growing, unique electronic control product manufacturer

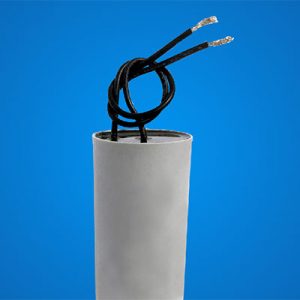

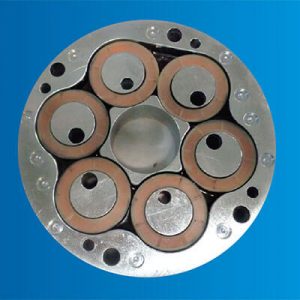

Application: NextGen ECUs

Process: Vacuum Potting

Challenges

The Client, a small lab-based enterprise which with NextGen ECUs, was fast growing into a leading manufacturer in the category. It wanted a technology partner to support the highly unique needs of this NextGen product range. As the Client was signing practically every major automaker in India and around the globe, it wanted a reliable, high production machine for vacuum potting process.

The range of products were based on new concept and even a slight failure in quality, performance or delivery would jeopardize client’s growth. With huge global market potential, willing investors, and a young team at the helm, the stakes were high. Impressed with Twin’s long standing legacy of developing innovative solutions, the teams joined hands

Solutions

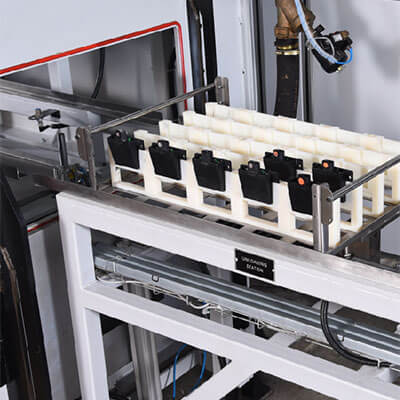

Twin’s R&D team invested time in understanding Client’s product, its potting process and production targets. The result, an equally game-changing product from Twin, the NextGen Fully Automatic Vacuum Potting Machine with which the client achieved all of its production and quality goals.

The fully equipped machine came with conveyor, integrated vacuum chamber and an X-Y Robotic dispensing station. The software took care of all the variants to be potted, as per their required mixing and dispensing configurations. The Machine has proved to be a strategic asset to Client’s production, and holds the key to its profitable growth.