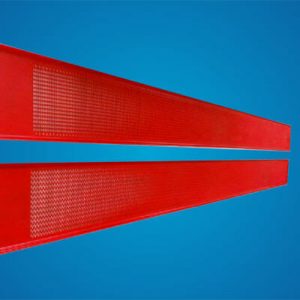

Cast Polyurethane Disks for Elevators

Know more…

Rejections reduced by 70% with better quality Polyurethane (PU) Disks for elevators

Client: A Thailand based manufacturer of specialised Ealastomer Castings products

Application: Polyurethane Disks for Elevators

Process: MDI Material

Consumption: 10 Disks in a single go as opposed to 2 Disks when done manually

Challenges

PU disks used in elevators must be capable of pulling strong wires. Quality and durability is non-negotiable in these products. Thus, a Thailand based -based manufacture of PU disks rightly had stringent quality controls in place. However, when faced with much higher rejection rates for its products due to some performance problems, the company began to question its production process and decided to make deep changes to it.

Manual mixing in the Cast Elastomers process at the company caused a number of serious problems. Bubbles were observed in a large number of products, leading to poor quality and wastage of material. On top of that, manual mixing cost the firm considerably in terms of time and business opportunities. Even meeting its daily targets was becoming difficult, and the company risked losing a number of business orders. Finishing also had to be perfect as the application involved rough operating conditions and high risks of damage or rupture.

Solutions

The situation called for a solution that could help ensure faster and better quality results. Keeping this in mind, Twin Engineers narrowed down on the three-component machine with plasticiser mixing. The machine with a flow rate 3 kg/min, enhanced throughput while ensuring reputability easier and highly accurate.