Machines for Battery Lid Sealing & Terminal Potting

Watch Video

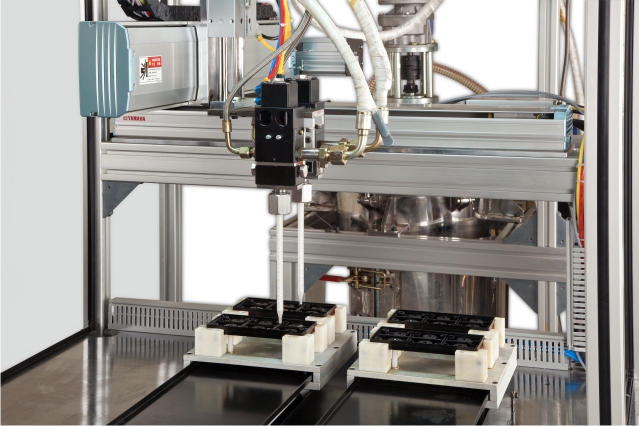

Highly dependable, fully automated systems for Battery Lid Sealing and Terminal Potting

Seal strength between the battery and lid is critical to the long-term performance of VRLA batteries. Twin offers standalone, compact and automated Meter Mix Dispensing Systems for Cover Sealing Application in small battery covers.

The systems can be connected with wide range of options and automation solutions for upstream or downstream activities in order to configure the ideal process parameters for your applications.

Machines we offer

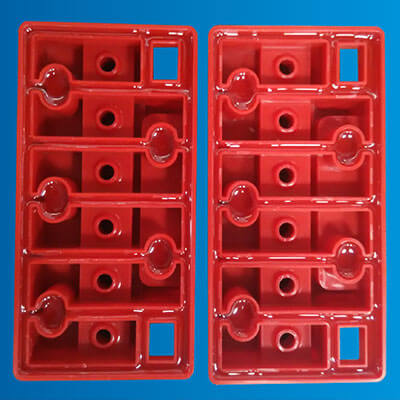

Easy to use , Compact MMD systems for Battery lead Sealing

Standard Features

MMD system with double metering and mixing heads for higher production rate

Can be configured for different sizes of Batteries

Productivity 5,000 – 6,000 lids/shift (VRLA battery lid of size appx. 150 mm x 65 mm.)

Specifications

| Shot Size | Adjustable |

| Flow Rate | 0.5 gm/sec to 10gm/sec |

| Tank Size | 10/45/60 ltr |

| Degassing | Vacuum Degassing for Resin Tanks |

XY Robot for point to point dispensing

Ensure seamless and quick commissioning of batteries with Twin’s advanced meter mix dispensing system. System can handle all varieties of Epoxy and PU glues used in lid sealing applications

Advanced electronic controls with touch based HMIs

Variable ratio, Precision metering gear pump

Static or Dynamic Mixer for homogeneous mixing

Compact structure with aluminium frames