Blog

A world made better and safer with composites

Composite materials are now everywhere – from automobile to insulation, interiors to aerospace. There are many reasons that manufacturers opt for composite materials for their applications – owing to the flexibility to tailor the composite’s properties according to the specific requirements. With the endless possibilities that come with composites, they have become truly valuable in today’s world.

Understanding Composites

But what exactly is a composite? A composite material is, simply put, two components which when combined give greater strength than their individual components, resulting in them giving superior results. Composites are of many types – Polymer Matrix Composites which are made by combining resins and epoxies with reinforcing fibers to create specialized materials, Medical composites – that are used in medical devices, composites used in automotive, composites used in consumer goods, and so on.

Composites in India

In India, the per capita consumption of composites in 0.3 kgs as compared to 11 kg in the USA.

As the country is progressing and developing, so is this sector – the growth potential being huge

According to a report by Grand View Research Inc, the composites market size is expected to reach USD 130.83 billion by 2024 due to the rising demand for lightweight materials for the automotive and the aerospace industries. The Make in India initiative by the Government of India has also given a boost to this industry in the country. The current composite market in India stands at an estimated 3.4 lakh metric tonnes.

Growth of the industry in India and the potential

This growth of composites in India is also highlighted by demand from industries such as Mass transportation, electricals and electronics, renewable energy, etc. The Indian wind energy industry has also grown dramatically over the last two years with India adding a record 4,148 MW of wind capacity in the year 2017. The country is also witnessing an important role for Thermoplastics and Thermoset Composites penetration in the automotive industry. The Indian automotive industry is growing tremendously with FDI inflows worth USD 15.06 billion from April 2000 to March 2016.

Twin Engineers – The pioneers in the Indian composite industry

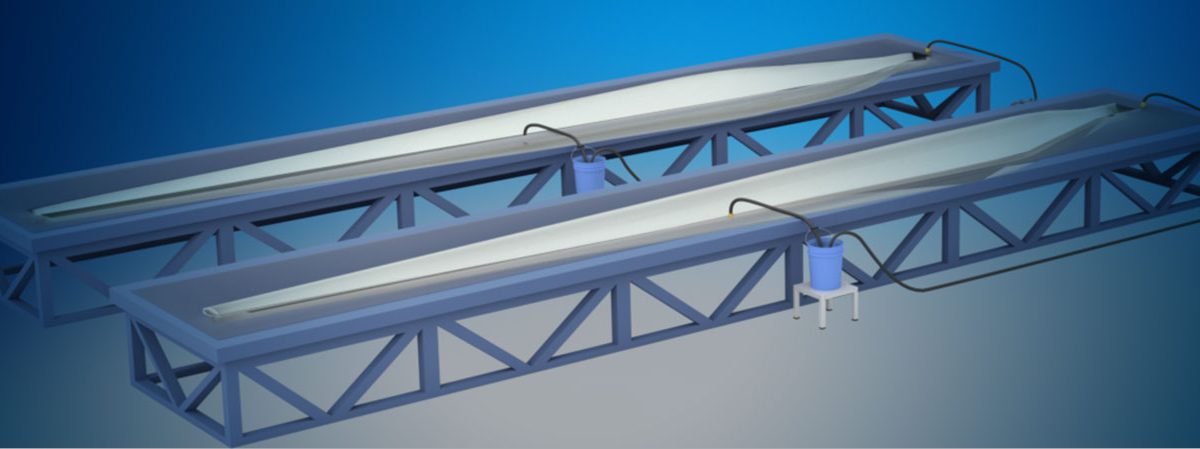

At Twin, we entered the composite industry 5 years ago with India’s first machine for resin-infusion in wind rotor blade manufacturing. We have come a long way from there. Our machines are now extensively used across industries for tanks, composite cylinders, pipes, kayaks, and surfboards. With our expertise in epoxy/resin dispensing for processes like infusion, RTM, Pultrusion, & Bonding & Sealing processes, we have helped several international and national names further their manufacturing agenda for solutions created with composite materials.

Where we have stood apart is in helping to deliver automation. These processes are inherently hard to automate. In that scenario, automating mixing & dispensing is the first step for many enterprises when looking at scaling-up production. Our wide applications range makes us the only Indian company addressing so many industries.

Why are we a name that’s trusted across the globe?

Our clients trust us for our reliable and low maintenance machines. We partner with them to understand their requirements and work as a team to deliver the best results. Our technology is advanced, and our price is in line with industry norms. With our expertise in materials, processes & applications, our partnerships with the composite manufacturers are constantly growing.

Why are we a name that’s trusted across the globe?

Our clients trust us for our reliable and low maintenance machines. We partner with them to understand their requirements and work as a team to deliver the best results. Our technology is advanced, and our price is in line with industry norms. With our expertise in materials, processes & applications, our partnerships with the composite manufacturers are constantly growing.

Why are we a name that’s trusted across the globe?

There is, without a doubt, great scope for the Indian composites industry to cater to the global market and grow substantially. It is also expected that India’s composites consumption will grow exponentially in the next 5-10 years. And we at Twin, are geared to cater to this market and its needs. With our advanced machines, solutions, innovation and our DNA of working as our client partner’s team to address their business requirements, we believe we are well placed to add a considerable range of success in the composites area over the years to come.