Electromagnetic brakes

Know more…

Client: Market leader in electromagnetic brakes

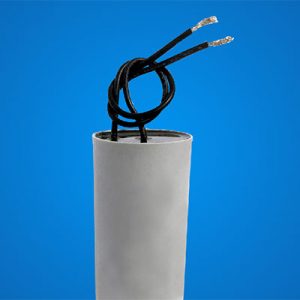

Application: Electromagnetic brakes

Process: Vacuum Potting

Challenges

India’s largest manufacturer of electromagnetic brakes was looking for a reliable partner to automate vacuum potting for its critical products. Relatively complex profile, multi-stage potting under vacuum to withstand harsh operating conditions when in use were the key challenges.

Twin was selected owing to its vast and proven expertise in vacuum potting, along with an unparalleled commitment to proving the application.

Solutions

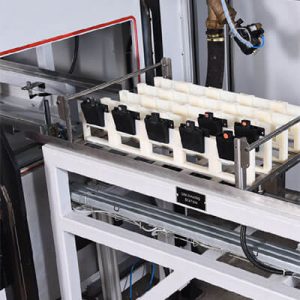

Twin’s team worked closely with product design and production functions at the client’s end to develop a vacuum chamber, integrated with Meter Mix machine, and robotic dispensing capabilities.

The entire process was automated saving time and effort while providing complete assurance of quality. The solution ensured accurate potting, for two stage process, in a single unit passed all the tests at client as well as the end-client’s applications.