Bushings and Insulators

Know more…

Client: A fast growing transformer manufacturer

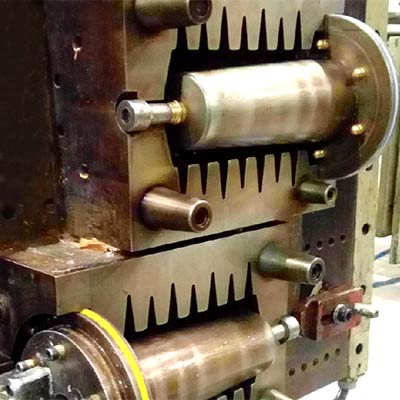

Application: Bushings and Insulators

Process: APG

Consumption: 500 Kg/shift

Challenges

The client wanted to automate its mixing and dispensing, in view of fast growth, and chose Twin as a technology partner to achieve the same. Twin suggested its proven, Epoxy Casting Plant which combines silica filling, preparation mixing and dispensing in a single system. With 4 APG Stations, Client wanted an economical solution for the set-up.

Solutions

Twin adapted its system to Client’s budgets and process needs and provided a unified set-up where the APG Stations could directly be connected to the mixing and dispensing unit. Twin’s team studied the client’s process, suggested the optimum layout considering the movement of materials, storage of raw materials, moulds and finished components.

The Epoxy Casting Plant ensured the best quality, while maximizing the production by multi-fold as compared to the conventional mixing and dispensing processes. The entire system was built and supplied within budget, as the Client earned significant cost savings in terms of lesser labor and lower material wastage, from the very first day of operation.

Key Benefits

– Significant savings in capital and operations costs

– Far lesser maintenance, assured system uptime & greater throughput

– Total quality assurance with fully automated process